Regular readers will know that we had the gas supply removed from our home in April this year. This left us with no central heating in our home. We used a portable 400 W electric infra-red heater in he living room on some of the cooler days of March and April, which worked well enough for those months because our home is now very well insulated, but we knew that in the middle of winter we'd need a more effective form of heating. Having the gas supply taken out meant that we were working under a time constraint - we had to find a solution before next winter. We now have that solution.

Electrical heating

Electrical heating is 100% efficient. All the energy which goes into an electric heater will be turned into heat. Actually, the same thing applies to all other electrical appliances - some of the energy may turn into mechanical movement, calculations, light, sound etc. but it all becomes heat in the end. So everything electrical helps to heat your home at almost exactly 100% efficiency (we lose a tiny bit from light shining out of windows and other small effects).

But just because resistive electric heating is 100% efficient that doesn't mean it's actually a particularly good way of heating your home. Electricity costs more per kWh than gas. Also if gas is being burnt to generate electricity then due to inefficiencies of the power station and transmission lines more gas will be burnt in total to heat your home than would be the case if you had an efficient modern gas central heating boiler.

For a while, around 50 years ago when the future looked like it might be nuclear powered, the idea of storage heaters was popular as they would allow excess "too cheap to meter" electricity generated at night by non-throttle-able nuclear power stations to be used as heat during the day. Homes in the UK were built as "all electric" and I lived in some homes with that type of heating. It worked reasonably well. There was a logic to it, but nuclear is not a technology which is going to come along and quickly save us from ourselves right now. Many of those homes were later retrofitted with gas, which now looks rather unfortunate. Our home in the Netherlands has gone in the opposite direction. Built originally against a promise of cheap endless gas, we've transformed our home to be fully electric.

Heat pumps

Heat pumps on the other hand are popular now. They appear to do something magical in that they generate more heat energy in their output than they consume as electrical energy from their supply. There is of course no magic involved at all. In this house we obey the laws of thermodynamics and we're not creating something out of nothing. Heat pumps actually (mostly) just move heat around. When heating a home in the winter they take heat out of the already cold air, water or ground outdoors, making it even colder, so that that heat can be emitted indoors. It's a neat trick.

The problem with heat pumps sold to replace central heating boilers, providing hot water to flow through radiators or under-floor heating, is that they're very expensive and they're over-sized for many well insulated homes. When I calculated how much gas we burnt last year to heat our home it became obvious that the 28kW gas central heating boiler installed in our home had only burnt enough gas to have operated at full power for the equivalent of about three days in the whole year. The lowest output heat pumps are rated at around 7 kW so one of those would have to run for about 10 days in the year. It would still lose a little in efficiency because the boiler would be on the top floor and the hot water would still have to be piped two floors down to reach the living room, losing some of the heat along the way (even with well insulated pipes), but total energy consumption would be 400 kWh over the year. By comparison, direct electrical heating to provide the same amount of heat would consume about 2000 kWh of electricity in total.

Air conditioners

Air conditioners work in exactly the same way as a heat pump. Many models of air-conditioner can also operate as heaters and when so used they have the same high efficiency as heat pumps. i.e. they produce far more heat as output than they consume from the electricity supply. Even though they don't attract a subsidy they have a much lower price than a heat pump, so we decided to install an airconditioner as our source of heating in the winter.

We could have installed two air conditioners, one up and one down, but we're instead going to try to live with just one in our living room together with occasional use of a portable electrical heater upstairs should it prove to be necessary. We have rarely turned on the upstairs radiators in our home in the past so we clearly don't have much need for heating upstairs, but if it turns out to be necessary nothing excludes the installation of a second air conditioner upstairs. Two air conditioners still cost only about half the price of a heat pump.

The nasty environmental problem with air conditioning and heat pumps

One of the things that has put me off both heat pumps and air-conditioners in the past is the high environmental impact of florinated refrigerant gases. These not only have a disastrous effect on the ozone layer but that also can have a greenhouse effect greater than 10000x that of an equivalent amount of carbon dioxide (GWP = global warming potential). Even the R32 refrigerant often touted as environmentally friendly has about 670x the global warming potential of the same amount of CO2.

While it's supposed to be the case these days that refrigerant is recovered when airconditioning systems are taken out of use, does that actually happen in reality ? Photos showing destroyed airconditioning units dangling from buildings in war-zones and after natural disasters indicate that a considerable number of these units don't get decommissioned in a manner which is sympathetic to the environment, and even if they are, what do we do to ensure that those gases never escape once they are extracted from an old airconditioner? I'm not convinced that these gases can be contained for the rest of time and do all the old gases make their way safely to one of the few plants which can destroy them ? I don't think I'd like the answers to these questions. Luckily, there is an alternative:

The solution: R290

R290 is a refrigerant with a GWP of just three. Not three hundred or three thousand, just three. On release it has a greenhouse effect only three times as bad as CO2 and it has no no effect on the ozone layer. There is very little refrigerant in an airconditioner, less than half a kg. As such, the total harm than can be done by releasing this gas is very small. R290 is actually just propane, so not a florinated gas at all. As a result of this it's also legal for people to work on R290 systems themselves. No "f-gas certificate" is required for working with R290 here in the Netherlands because it is not an "f-gas". DIY is good - it should reduce the total cost and I like doing stuff.

Our choice of airconditioner

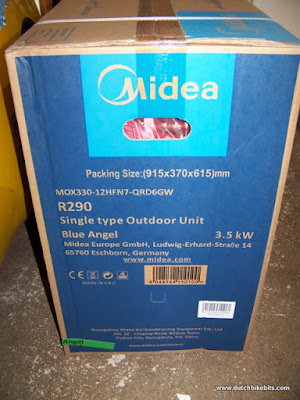

R290 split airconditioners have been promised for some years but they still seem to be new on the market. I picked the only model that I could find on the Dutch market earlier this year, a Midea 3.5 kW air-conditioner. This was the first model of airconditioner ever to win German Blue Angel environmental certification. It took a while to find a supplier as seemingly not many people sell them, but I did find a supplier in the Netherlands.

As this airconditioner has an SCOP of 5.2 it will in principle consume only about 400 kWh of electricity a year to provide as much heat directly in our living room as our old central heating boiler put into hot water which it then pumped around the house. It should operate efficiently down to -15 C which is almost as cold as it's ever been here. It's never been that cold for the entire day. But anyway, if it gets really cold I guess we'll have to go out cycling for a bit to warm up.

To provide power we already expanded our solar power installation with two extra solar panels which will produce about 700 kWh of electricity a year. In total we should easily generate enough electricity each year to supply the air conditioner as well as the electric water heater (for which we installed another two solar panels) and every other electrical device in our home. While in winter months even our over-sized solar setup won't generate enough to run everything, the overcapacity should mean we are able to operate at least mostly on our own electricity for most months of the year.

Now some DIY

The airconditioner turned up a couple of days after ordering and then I ordered a few extra parts to complete the installation.

|

| The outdoor unit in a box. Clearly labelled R290 / Blue Angel. Quite heavy to move. |

I needed refrigerant lines and electrical cable and I chose rubber feet for mounting the outdoor unit on the ground outside our home. We could have mounted it on the wall but I thought that brought a higher possibility of vibrations being carried into our home (the unit doesn't vibrate much and I now doubt this would have been an issue). Also the wall mounting brackets available didn't seem to be large enough to allow enough space. The outer unit is recommended to be installed 30 cm from a back wall for maximum efficiency.

The first thing was to determine the best place for the inner unit. I decided to place it half way along our living room wall and so high as possible. The instructions suggest a minimum of 15 cm between the unit and the ceiling and that's about the height at which it's mounted. I didn't want visible ducting inside our home so I drilled a single large hole through which all the pipes and wires had to run. This had to run downhill to the outside in order to make sure that the condensate would find its way out through the wall, and in my case I had to run it at a more extreme angle than I otherwise would have because the carport outside our home is attached to the outside wall at the same height as the inner unit of the air conditioner is on the inside wall.

The refrigerant tubing comes as a reel of copper pipe with insulation already fitted. I was cautious of bending this copper tubing as I'd expect it to flatten if bent too sharply but it unwound without causing any harm to itself and could be poked through the wall to the other side also without harm. I could then attach the pipes on the outside to the external unit. In my case exactly three metres of pipe was required. This was supplied with the required flare to fit both units, making the job a bit easier.

By this stage I'd put everything together so that in theory it was ready to go, I then tried to find a contractor to carry out the final step: Before you can set an airconditioner into operation it's necessary to draw a vacuum in the pipes so that there is no air in the system. Only after that has been done is it possible to release the refrigerant from the outdoor unit into the system. Some people don't bother with this step and I assume that their airconditioners don't operate to their full potential as a result.

I didn't have a vacuum pump and I thought it reasonable to let someone with experience do this part of the job for me. I even thought it might save a bit of time. However that turned out not to be the case at all. This was the most time consuming part of the whole project ! I waited over a month for more than ten different contractors to get back to me. They either said they would only with a certain manufacturer's airconditioner, or they wouldn't check other people's work, or they said they were too busy. Eventually, one guy said he'd come and do it. He made an appointment for two weeks in the future... and then he didn't turn up. So this was also to be a DIY job.

The standard price for setting an airconditioner in action is €200. That's what everyone who said they could do the job said they'd charge me, though none of them seemed to need the money. In the end I bought a vacuum pump for €115 expecting to need adaptors and pump oil in addition, but it turned out that everything I needed was in the box with the vacuum pump. This was a very simple and quick job to do, apart from the waiting around. No more than half an hour of actual work.

|

| Vacuum pump pulling the air out of the tubing. After half an hour I turned off the blue tap and disconnected the yellow hose. |

, which was never an option , which was never an option |

| The next morning we still have "-1 bar" relative to ambient air pressure so it didn't leak (i.e. close to 0 bar in reality negative pressures can't exist) |

So the pump was set up and drew a vacuum for half an hour. I then I disconnected the pump, leaving the pressure gauge displaying -1 bar overnight. After that I let some of the gas into the system, the pressure rising to about two bar so that I could check my connections to the pipework with soapy water to see if there were any leaks (which I'd have to tighten up before going further). There were no bubbles forming so I let the rest of the gas into the system, still no bubbles, then I removed the meter from the outdoor unit, fitted all the covers and switched on. The airconditioner works.

We have a heating solution!

So we now have a heating solution for next winter. It will consume less electricity than a heat pump but hopefully provide us with enough heat. It's a bit of an experiment for us to say that we're only going to heat the ground floor, so wish us luck. The kitchen is a bit of a worry because it's around the corner from the living room and dining room. But the kitchen also has other heaters in it, such as a small water heater under the sink, the refrigerator etc. The extra insulation job that I did on the kitchen door a few days ago was specifically intended to try to keep the kitchen warm when we are heating just the living room. We have other plans and there are more things that can still be done. Watch this space.

Did I forget to mention summer ? We installed this air conditioner primarily to provide heat in the winter, but obviously an air conditioner can also be used as an air conditioner. We have done that for a couple of afternoons when it was very hot and I have to say that it's very pleasant to have a cooler home when it's hot outdoors. Luckily these times also coincide with our having excess solar power and the grid being quite full due to the amount of sun beating down on everyone's homes, so we find ourselves still exporting electricity while the airco runs. I don't see a downside to using the air conditioner in this way sometimes. With weather becoming more extreme we might well use it more often. But we don't intend to live in a permanently air conditioned home. When the weather allows, it's much nicer to open the windows.

Getting rid of the radiators and central heating boiler

A job that I've not yet done is to get rid of the radiators and central heating boiler from our home. There's a lot of metal involved, a lot of heavy work. They take up a surprising amount of space. We didn't get rid of these things when we first had the gas removed because that would mean burning a lot of bridges. We might have decided to install a heat pump instead of air conditioning, and that could have worked with our existing radiators (which are oversized to suit our originally under-insulated home). While I'm quite confident, this also means that if the air conditioner doesn't work out this winter, we could still make use of the radiators next year with a heat pump. There's no need for us to rush this.

Car airconditioners

What's the deal with car air conditioners ? From what I can tell these leak all the time and drivers respond by having them "topped up" with more refrigerant, sometimes annually. If there's a crash (and there are always crashes) then the refrigerant is released and having its awful effects on our climate and the ozone layer. Air conditioning in cars really should not be allowed, certainly not with use of refrigerants which are more destructive to the environment than R290.

Update: The first cold month - November 2023

November this year was colder than usual. We had snow and persistent freezing temperatures which we've not had in November for many years. There was also very little sun. So how well did the heat pump work ?

|

| Gas usage November 2022. We consumed 52 m3 of gas, compared with 119 m3 for an average apartment and 217 m3 for an average house like ours. |

In November 2022, which was warmer than this year, we used 52 m3 of gas for heating. That was less than half the amount used by an average apartment in the Netherlands. This year we substituted 105 kWh of electricity consumed by the heat pump. 105 kWh of electricity is equivalent to the energy released by burning about 10 m3 of gas so we're now heating our four bedroom semi-detached home with about 1/10 of the energy required to heat an apartment.

And the CO2 footprint ? Burning 52 m3 of gas results in the release of 92 kg of CO2. The average gCO2/kWh for the Netherlands in 2022 is 321 g so consuming 105 kWh of electricity results in the release of 33.8 kg of CO2 on average. That's about a third of what we produced last year with gas. But even with the particularly grey weather that we've had for the last month we still generated 1/4 of the electricity that we used from our solar panels (and we used 80% of that directly, not relying on the grid too much as a "battery"), which brings us down to around 25kg, or not far from a quarter of last year. We're signed up to an energy contract which promises "100% green" electricity but while that provides a stimulus for green energy producers it doesn't really change what comes from the grid. I hope of course that we're at least providing a push towards producing greener electricity.

But even in the worst case we're looking at a far lower CO2 output than the 386 kg which an average semi-detached house like ours produced last November.